Technology Readiness Level (TRL) is a measurement system used to assess the maturity of technology. TRL framework is often used in research & development by engineers, project managers, investors and grant decision-makers. It provides a common understanding of the status of technology throughout its development. It’s incredibly useful for project and risk management and budgeting and is almost always mandatory for successful funding applications. There are nine stages in the TRL framework; TRL 1 is the first, and TRL 9 is the final.

TRL 1 – Basic principles observed and reported

The first stage is discovering, understanding and establishing a theoretical foundation for your innovation. Proposals at TRL 1 should outline your research’s theoretical basis and potential impact. At this early stage, you don’t need to have a practical application in mind. Instead, it could be an investigation or a university study conducting background research.

TRL 2 – Technology concept or application formulated

TRL 1 lays the groundwork for TRL 2. You begin to consider how your ideas can be applied to create new technologies or improve existing ones. TRL 2 bridges the gap between basic research and practical development. Proposals at this stage will outline your technological concept and its potential applications. However, it’s important to note that raising funding for TRL 1 and 2 projects can be difficult. At this stage, nothing has been proven. For potential clients, we can take a project at TRL 2 as part of the scoping process and carry out the development work to add value and move the project to a higher TRL.

TRL 3 – Analytical and experimental critical function or characteristic proof of concept

Moving from the theoretical to the practical, TRL 3 is all about demonstrating the feasibility of your concept. You will conduct small-scale and low-risk experiments to test your theory and show that the key aspects of the technology work as intended. During this stage, you could identify unexpected problems that are only realised in a practical context. A proposal at TRL 3 will highlight your plans for validation, such as methodology and expected outcomes. Creating a proof of concept allows you to experiment with critical functions while minimising risks and costs before further development.

Example

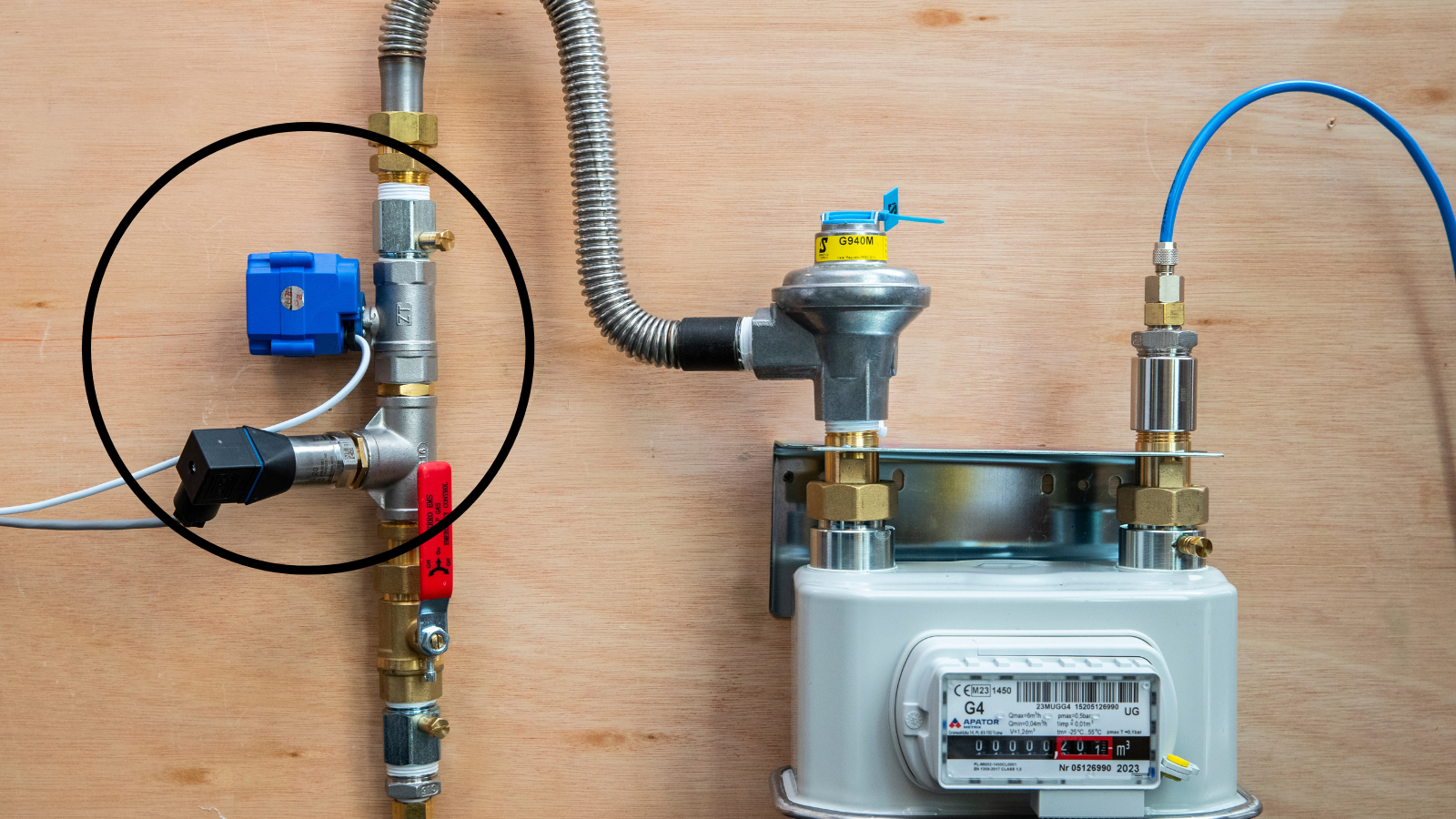

Proof of concept (circled) set up for in-house testing.

For DefProc’s Smart Gas Pressure Sensor, TRL 3 involved selecting and testing potential device components for the proof of concept. This ensured the proof of concept had the most appropriate hardware for its application. We tested the device in-house using air instead of hydrogen to keep this phase low-risk and low-cost. We verified the robustness of the materials and design and provided a summary of the tested sensors and results. This allowed us to choose the best sensor for the device and provide a rationale for making this choice.

TRL 4 – Technology basic validation in a laboratory environment

The next step towards practical application is testing your proof of concept. This requires a controlled testing environment (such as a laboratory) that simulates real-world conditions. Here, you can monitor and collect data to evaluate the proof of concept’s performance, identify any issues and refine and improve your design. For proposals at TRL 4, you will need to demonstrate how the laboratory simulates real-world conditions and how the data collected will be used to refine the technology. Collaborating with industry partners to provide expertise and resources for testing may be necessary.

Example

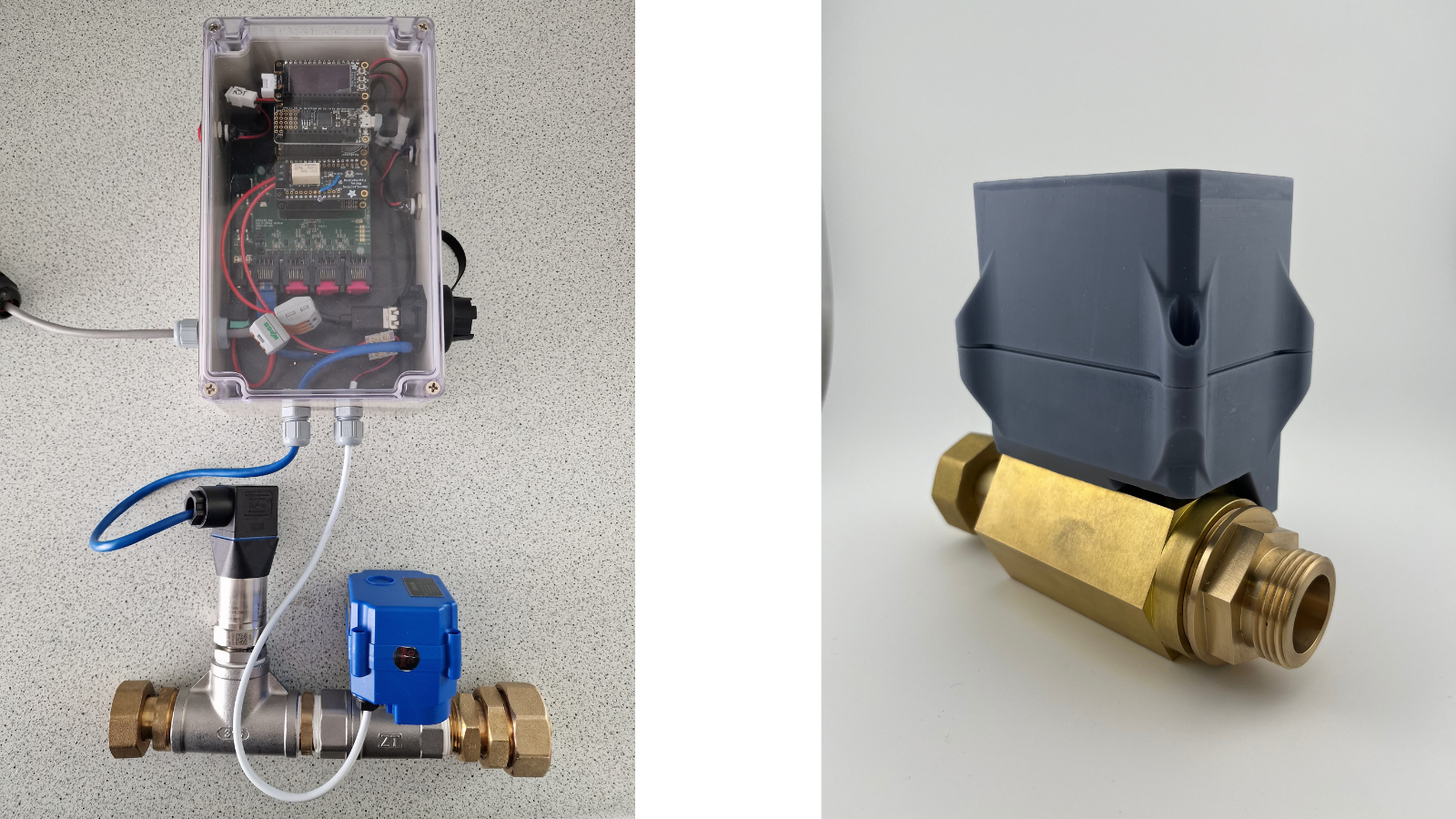

Left: TRL 4 Proof of Concept tested at DNV. Right: TRL 6 prototype device.

Following the creation of a Smart Gas Pressure Sensor proof of concept, DefProc was required to test it in a laboratory environment. It was sent to DNV where it could be tested with hydrogen instead of air. This allowed for validation that the device worked with hydrogen flow under the supervision of a third party. The results of testing at TRL 4 were measured with the results at TRL 3. Any unexpected effects from the change of environments could be identified before moving forward to create a prototype.

TRL 5 – Prototype basic validation in a relevant environment

The next stage sees the development and validation of a prototype in an environment that closely resembles real-world conditions. It’s crucial to demonstrate the technology’s functionality, reliability and scalability. This stage may include testing in simulated operational settings, outdoor field testing or controlled industrial environments. For proposals at TRL 5, you will need to outline your plans for validation, including the design and details of the system, testing environment and performance metrics. The aim is to bridge the gap between laboratory confirmation and full-scale deployment.

Example

After testing in a laboratory environment, we began developing prototypes for validation in a relevant environment. For DefProc’s project, H2Go, this meant redesigning the mechanics and electronics as the design brief specified it should resemble a smoke detector. Thanks to testing at TRL 4, we knew that the technology worked. However, it did reveal minor issues that had to be revised at TRL 5. To address this, we set up a testing rig close to what the final device would operate in. We tested sensors for stability (long-term tests in open air), changes from varying temperature and humidity levels and concentrations of hydrogen. Measuring the results can identify problems only discovered from testing outside of a lab. It’s not unusual to encounter problems at TRL 5. For our clients, we highlight and test any risks as early as possible so we can solve them before they become an expensive problem!

TRL 6 – Prototype demonstration in a relevant environment

TRL 6 tests the technology in a relevant operational environment close to its final intended application, such as an industrial site or commercial facility. The prototype at this stage will have all the key components and features of the final product. This allows you to verify the technology’s performance, reliability and durability under realistic conditions. Data will be collected to identify any remaining issues and ensure the technology meets the required standards and specifications. Proposals will need to detail plans for large-scale testing, including the design and specifications of the prototype, testing environments and performance metrics. You will also need to highlight how the operational testing will replicate real-world conditions and contribute to the final validation of the technology.

Example

Following the development of the H2Go prototype at TRL 5, TRL 6 marked the creation of a fully functional prototype ready for external testing at Health and Safety Executive Laboratories (HSL). This was to confirm internal findings and carry out wider testing with more precision. The results from HSL provided stronger results for the H2Go device and confirmed that the technology worked under various conditions that closely resembled its intended environment.

TRL 7 – Prototype demonstration in an operational environment

The next step requires the demonstration of your technology prototype in an operational environment. This might sound similar to TRL 6. However, the focus at TRL 7 is installing and testing the technology for initial performance validation. The prototype will be almost identical to the final commercial product (at TRL 6, it might not be fully optimised for operational use). The testing environment is typically where the technology will be used. This allows you to verify system installation and integration and carry out initial performance assessments. TRL 7 proposals should share your plans for the system prototype demonstration, testing environment and performance metrics. You can also show how the operational testing will validate and prepare the technology for full operational use.

Example

With the H2Go devices proven to work in a relevant environment, we could deliver them to their intended operational environment for demonstration. In this case, the devices are currently at NGN’s Low Thornley Hydrogen Homes test site in semi-detached homes fitted with hydrogen equipment as a technology demonstrator.

TRL 8 – Technology completed and qualified through test and demonstration

The penultimate TRL stage entails the final integration and validation of the technology in its intended operational environment. You will demonstrate that the technology is fully functional, reliable and compliant with the required regulations. This will prepare you for full commercial deployment, ready for market entry. Monitoring and testing, such as real-time data collection, will identify any final issues. Technology at TRL 8 must comply with the relevant regulatory requirements and have conducted any testing necessary. Project proposals should detail plans for active commissioning, operational testing and regulatory compliance, how the technology integrates into its environment and how you will validate its performance and reliability. TRL 8 is often the final stage for funding.

Example

Left to right: Push to Talk proof of concept, prototype and market-ready device.

DefProc’s Push to Talk device reached TRL 8, moving from a trialled and tested functional prototype to a fully certified product. To begin, we had to ensure we could manufacture the device at scale. This meant taking the existing prototype circuit boards and refining them for large-scale production. The same applied to the device’s casing. We worked with an experienced industrial designer to prepare for injection moulding, allowing us to manufacture in multiples of 100. Another critical step was the EMC and regulatory testing of the devices and the creation of a product technical file. This was required for Push to Talk to be market-ready (UKCA marking) and for deploying to users’ homes. We also considered the identity and branding of the product at this stage to support a greater understanding of the service, installation and operation of the device, ready for TRL 9.

TRL 9 – Technology qualified through successful operations

The final stage will mark your technology as fully operational and deployed in a real-world environment. Ongoing maintenance, support and upgrades will ensure the technology remains functional over time. Proposals could focus on further market penetration, expansion and scaling up operations. You might have to provide details on operational performance, user feedback and plans for maintaining and upgrading the technology.

We support clients getting to market with their products. Whether you’re at TRL 1 and need an end-to-end support package, or you’re looking for technical support for a prototype, DefProc can offer a bespoke solution for your needs.